- Home

- ENGINEERING PLASTICS

Description and Properties of Engineering Plastics

Engineering plastics are characterized by their mechanical, electrical and thermal properties. Engineering plastics retain their properties above 100 ° C and below 0 ° C, so they can still be used permanently at temperatures like 150 ° C.

Polyamide 4.6 (PA 4.6)

Compared to other polyamides, Polyamide 4.6 (PA 4.6) is the most fatigue-resistant of all. The thermal dimensional stability is high. PA 4.6 is more chemically stable and crystallizes better than PA 6 and PA 6.6. When other polyamide types do not perform, polyamide 4.6 retains its properties at elevated temperatures. Its applications are similar to other polyamide types and PA 4.6 is used in electronic and electrical components.

Polyamide 6 (PA 6)

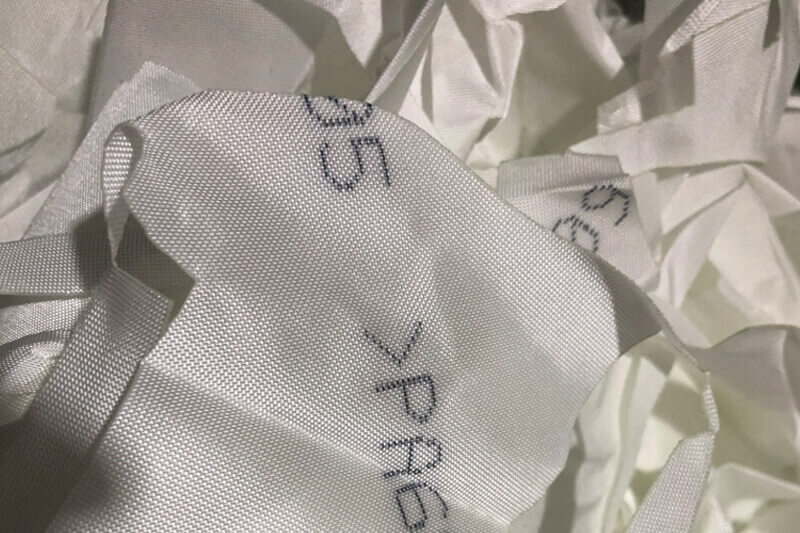

Polyamide 6 (PA 6) is a partially crystalline polyamide, which is characterized by ductility and abrasion resistance. PA 6 is used for the development of nonwovens. These fabrics are easy to dye and glossy. Polyamide 6 (PA 6) is also used to make threads, nets, ropes and knitwear.

Polyamide 6.6 (PA 6.6)

Polyamide 6.6 (PA 6.6) has a high melting point and a high abrasion resistance. Therefore, PA 6.6 is preferred in the manufacture of machine parts. Due to its extreme heat resistance and strength, polyamide 6.6 is the most commonly used thermoplastic material. PA 6.6 has good elasticity and high mechanical strength. It is used for the production of carpet fibers, electrical insulation elements, bearings, gears and conveyor belts.

Polyamid 6/66 Copolymer (PA 6/66)

PA 6/66 is the copolyamide of PA 6 and PA 66. It combines the properties of PA 6 and PA 6.6 Polyamide 6/66 copolymer is very popular in the industry for its durability, ease of processing and sustainability. The PA 6/66 copolymer has improved flowability in injection molding and greater clarity in film extrusion applications.

Polyamide (PA)

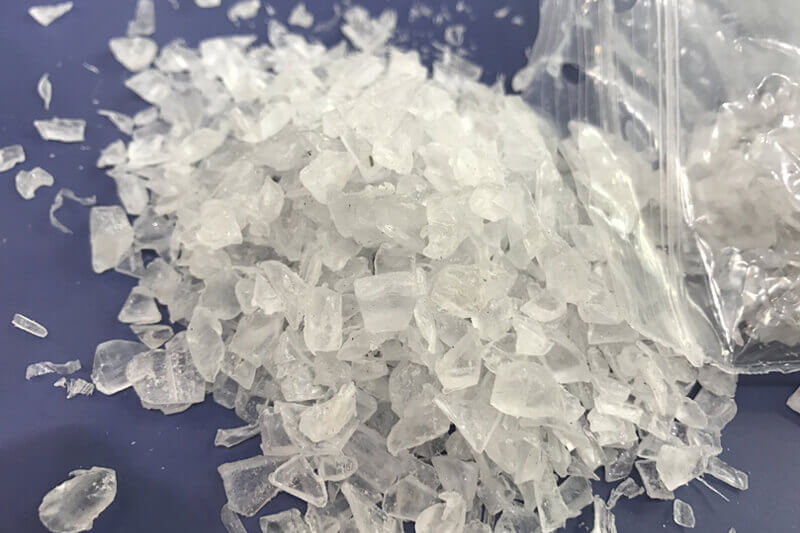

Polyamides (PA) are linear polymers with regularly repeating amide bonds along the main chain. The term polyamides is commonly used as a term for synthetic, technically usable thermoplastics. Almost all important polyamides are derived from primary amines. Polyamides are partially crystalline thermoplastic polymers. Polyamides are often used as construction materials because of their excellent strength and toughness.

Polyamide 12 (PA 12)

Polyamide 12 (PA 12) can be easily worked into any shape or size. The wear resistance is so high that this polyamide is not attacked even with high-frequency cyclic loading. PA 12 is used for the production of cable ties, gaskets, sealing rings, protective covers, membranes and ski boots. Polyamide 12 is highly flexible and is therefore used to make tubes for automobiles and air ducts.

Polyphthalamide (PPA)

Polyphthalamides (PPAs) are semi-crystalline aromatic polyamides (PA). They belong to the class of thermoplastics. PPA differs in its properties from aliphatic polyamides and aromatic polyamides (aramids). Polyphthalamide-based plastics replace metals in areas where high heat resistance combined with high mechanical stability is required.

Polybutylene Terephthalate (PBT)

Polybutylene terephthalate (PBT, PTMT) is a thermoplastic. It is one of the polyesters and has properties similar to those of semi-crystalline polyethylene terephthalate (PET), but is more suitable for injection molding because of its more favorable cooling and processing behavior.

Polybutylene terephthalate (PBT) is widely used because of its high performance strength, rigidity, very high dimensional stability (significantly better than those of POM or PA) and good friction.

Polyethylene Naphthalate (PEN)

Polyethylene naphthalate (PEN) is a polycondensation-produced thermoplastic of the polyester family. PEN is prepared by polycondensation of ethylene glycol and naphthalene dicarboxylic acid dimethylester. PEN can be used as a copolymer PET / PEN or as a polymer blend PET + PEN and can not only be used as a homopolymer.

Poly Cyclohexylene Dimethylene Terephthalate (PCT)

Poly Cyclohexylene Dimethyl terephthalate (PCT) is a thermoplastic polyester. PCT is similar to polyethylene terephthalate (PET), with which it shares features such as dimensional stability and chemical resistance. PCT is also particularly resistant to high temperatures and hydrolysis. Polycyclohexylene Dimethyl terephthalate has good dimensional stability at elevated temperatures. PCT is used for electronic components such as connectors. PCT is also processed into filaments, fibers and fabrics that are used in industry as filters.

Polycarbonate (PC)

Polycarbonates (PC) are thermoplastics. Polycarbonates (PC) generally have a crystallite content of less than 5% and are therefore considered amorphous. Polycarbonates are transparent and colorless. They can, however, be colored.

PC is used in productions where other plastics are too soft, too fragile, too scratch-sensitive, too little dimensionally stable or not transparent enough. In addition, polycarbonate as a transparent plastic is, like polymethyl methacrylate (PMMA) or styrene-acrylonitrile (SAN), commonly used as a glass alternative. Compared to brittle glass, polycarbonate is lighter and more impact resistant.

Cyclic Olefin Copolymer (COC)

Cyclic olefin copolymer (COC) is a class of engineering polymers. Although only composed of olefins, COC is in contrast to the partially crystalline polyolefins such as polyethylene and polypropylene amorphous and therefore transparent.

The properties of COC can be varied over a wide range by changing the incorporation ratios of cyclic and linear olefins. For optical applications, the low birefringence of COC is interesting. In the field of medicine, the outstanding biocompatibility, in particular blood compatibility and the extremely low water absorption are to be emphasized.

Polyphenylene Ether (PPO)

Polyphenylene ether (PPE, polyphenylene oxide or PPO) is a high temperature resistant thermoplastic. It is rarely used in its pure form. It is mainly used as a mixture with polystyrene, high impact styrene-butadiene copolymer or polyamide.

Styrene Methyl Methacrylate (SMMA)

Styrene methyl methacrylate (SMMA) is a clear amorphous thermoplastic. SMMA has high transparency, high rigidity, excellent scratch resistance, good chemical resistance and very low moisture absorption. SMMA is relatively easy to process due to its very good flow properties.

Polymethyl Methacrylate (PMMA)

Poly (methyl methacrylate) (PMMA), also known as acrylic, acrylic glass or plexiglass, is a transparent thermoplastic that is often used in film form as a lightweight or splinter. PMMA is a resistant alternative to glass. PMMA is an economical alternative to polycarbonate (PC) where tensile strength, flexural strength, transparency, polishability and UV compatibility are more important than impact resistance, chemical resistance and heat resistance. It is often preferred because of its moderate properties, ease of handling, processing, and low cost.